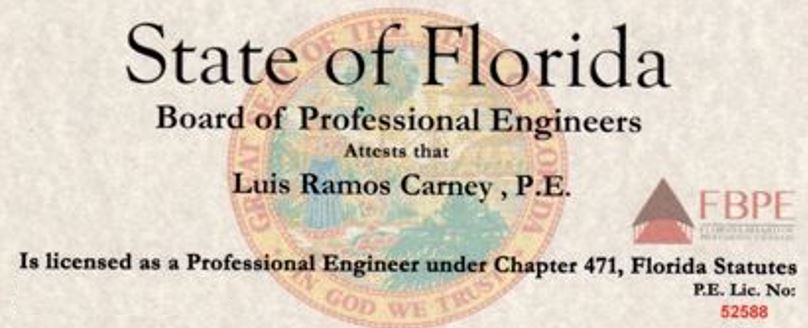

| Dr. Luis R. Carney, PE - Owner- FL Engineering License No. 52588 | |||

|

Specializing

In:

Failure

& Root Cause Analysis · Manufacturing Problems · Welding

· Corrosion · Design

· Heat Treat

· Materials Selection

· Brazing

· Forming · Forging

· Metallography · Shot

Peening

· Machining

· SEM/EDS

& More |

|||

|

Legal

· Aviation

· Industrial

· Transportation Dependable Support Anywhere Often Work In Jacksonville - Orlando - Tampa - Miami |

||

| Jacksonville Fl Office Serving The Continental United States: (904)-233-3660 | |||

| Home | About Us | Contact Us |

| Legal Projects | Engineering Projects | Aerospace Projects |

| EXPERTISE AND INDUSTRIES SERVED | |||||

| Corrosion | Welding | Failure Analysis |

Litigation

Support |

Manufacturing | Laboratory Work |

| Auto

& Trucking |

Aviation | Mechanical | Turbine

Engines |

Shipping | Industrial |

Engineering & Consulting Services

Customer

Service:

- Receive Timely, Respectful & Personal Attention On Your Case.

- Expert Testimony. We Make The Complex Understandable.

- Work Directly With Dr. Carney, Not A Lab Assistant.

- Fees & Estimates Discussed Up-Front. See "Cost of Services" Above.

- Dr Carney Speaks Fluent Spanish.

Our

Specialty Areas Include:

- Determination of Probable Cause of Failure and Who or What Might Be Responsible.

- Failure

Analysis of Components, Systems and Structures.

- Scientific, Reliable Support Throughout A Legal or Engineeering Case.

- Selection of Materials and Processes for the Engineering Application & Environment.

- Review of Mechanical Designs for Present or Future Problems.

- Product Development or Reverse Engineering - From Concept to Market.

- Evaluation of Corrosion & Control Methods, Especially Aviation & Industrial.

- Inspection of Welds, Failures, Design & Processing.

- Analysis of Fire, Electrical or Lightning Damage.

- Testing of Conventional or Exotic Engineering Alloys Including SEM/EDS/Metallography/Hardness and others.

- Engineering Applications of Polymers & Composites, Design & Failures.

- And A Lot More - Just Call or Email The Friendly Staff. Take Advantage of Our Initial Free Consultation at (904)-233-3660!

Aviation & Industrial Experience

Dr Carney's Qualifications

- Metallurgist & Engineer (metals, ceramics, polymers & composites) for the U.S. Navy (Aviation - Federal Civil Service) Since 1989.

- Started Southeastern Metallurgy in 2014.

- Degrees in Materials Science & Engineering from the University of FL '91, '95 and '06.

- Responsible for Approximately 125 Failure Analysis per Year.

- Currently Serve as a Technical Supervisor for the Metals and Ceramics Branch of Fleet Readiness Center Southeast - A Naval Aircraft Heavy Maintenance Facility in Jacksonville, Florida.

- Experienced in the Design, Repair and Overhaul of Aircraft Structures, Engines and Systems as well as the Complex Industrial Plant That Makes Such Work Possible.

Forensic Investigation Costs & Process

The costs associated with forensic engineering work vary widely. The principle factor, as you might expect, is the extent and complexity of the work. Costs are also negotiable and are typically not set in stone prior to initiating an engagement. Most engineering firms will discuss and provide estimates up front. Southeastern Metallurgy certainly does. Where a firm total is not possible, we provide our historical experience with similar cases and advise of any major changes along the way.

A typical forensic or metallurgical engineering failure

analysis consists of seven or more major separate parts: background,

visual observations, measurements and testing, electron microscopy,

metallography, materials

characterization, conclusions, and, if necessary, discussion. Each

part, in turn, may be broken down into sub-sections depending on the

needs and judgment of the metallurgist.

The

costs associated with a failure analysis are composed of the sum of

each of these parts. The costs associated with a deposition or court

attendance are apart from the composition of a report but should also

be available from an analyst or firm prior to a hiring decision. This

discussion focuses only on the laboratory report and associated work.

A

failure analysis may be simple (a single component failure) or complex

(a crash or massive structural failure) costs will vary accordingly. A

few rough approximations of the time and fees that would be associated

with a single component failure analyzed by Southeastern Metallurgy, LLC,

are presented below. Not all of the analysis indicated is always

necessary, an estimate based on your specific needs is always best.

Background Investigation: 2.5-5 hours of labor ($750-1,500).

Typical

activities: Gathering of information, drawings, specifications,

history, circumstances surrounding the event, interviews etc…

Visual Inspection, Measurements & Testing: 5-10 hours of labor ($1,500-3,000).

Typical

activities: Visual inspection accompanied by written, photographic and,

possibly, video documentation. Inspection and documentation using

optical microscopy (magnifications 5-30X). Manual measurements with

rulers, calipers, micrometers and gages (e.g. thread gages), simple

tests as required

etc…

Scanning Electron Microscopy and X-ray Microanalysis: 2.5-5 hours of labor + equipment fees ($1,000-2,150).

Typical

activities: Analysis of microscopic fracture features under an electron

microscope. Identification of fracture origin, fracture mechanism,

microchemistry, contributing factors etc…

Chemical Analysis and Materials Characterization: 2.5-5 hours of labor plus + equipment fees ($1,000-2,150).

Typical

activities: Determination of compliance with specified chemical

composition and required mechanical properties. For example, chemical

analysis by glow discharge spectroscopy (GDS) and tensile testing to

determine yield strength, ultimate tensile strength and elongation.

Metallography: 2.5-5 hours of labor + consumables ($750-1,500).

Typical

activities: Visual inspection under a specialized inverted microscope

(5X-1000X magnification) for measurement of small dimensions (tight

radii, plating thickness etc…) and metallurgical microstructures.

Written and photographic documentation.

Final Report: 8-16 hours of labor ($2,000-4000).

Typical

activities: Writing up the analysis with supporting pictures,

measurements, chemical analysis and tests data as necessary. Reporting

supported conclusions and, if necessary, a discussion of the findings.

Totals:

The

total cost for the hypothetical routine forensic or metallurgical

failure analysis described

above would range from $7,000

to $15,000.

The exact cost is obviously

highly dependent on the precise facts of the case. Southeastern Metallurgy will

be happy to provide a more precise estimate based upon your unique

circumstances. Feel free to contact us at (904) 233-3660.